IPON STRATEGY

WHO WE ARE

IPON is established in August 2012 to provide services in the Offshore and Onshore Oil & Gas Industry. The aim is to become a leading Oilfield Equipment and Service (OFS) company and a great entity in business.

IPON MVV

MISSION

To achieve excellent development and return for shareholders by delivering technology and services that improve efficiency, effectiveness, and maximize productivity for IPON clients.

VISION

To be a leader in the energy industry, ensuring the gradual increase of profitability in our operations.

VALUE

To endorse organizational culture and personal skills focused on Situational Planning, Effective Agility, Futurism, Innovation, and Synergistic Integration.

SAFETY

IS FIRST IN ALL WE DO

For us, safety is first in all we do. No business objective is so important that it will be pursued at the sacrifice of safety. Followings are key elements of IPON’s HSE mindset:

> HSE Solutions Tailored to the Client’s Needs

> Requirements of Culture of Zero Harm

> Environmental Sustainability

> Environmental Performance

> Air Emissions and Greenhouse Gases Sustainability

Learn more…

IPON’s sustainability commitments encourages us to continue with a leading governance model to ensure enhanced collaboration among and between critical units within the Company to best assess risk, identify opportunities for risk mitigation, and improve visibility to key stakeholders across the organization.

Learn more…

IPON LIFE Rules

10 to zero

- Driving Safety

- Personal Protection Equipment (PPE)

- Confined Space

- Chemical Handling

- Hand Tools

- Work Permit

- Lock Out/ Tag Out (LOTO)

- Working at Height

- Working at HeighDropped Objectst

- Lifting and Hoisting

IPON WORKSTYLE

OUR TRAINING CENTER

Learn more to earn more

Avid is a privately owned training center with the objective of providing core knowledge and job related skills to the individuals involved in energy sector. We don’t just believe in ensuring that the candidates pass the exam; we also ensure that they learn and understand and finally are able to use the learnings in their practical scenarios on the job.

Our Courses

– Introductory Courses

– IWCF Courses

– Advanced Well Control

– Drilling Operations

– Well Intervention Operations

– Well Engineering

– Well Integrity

– Online learning

– Rig & Well Equipment Courses

– Well Control Equipment

IPON SERVICES

OUR WELL INTERVENTION SERVICES

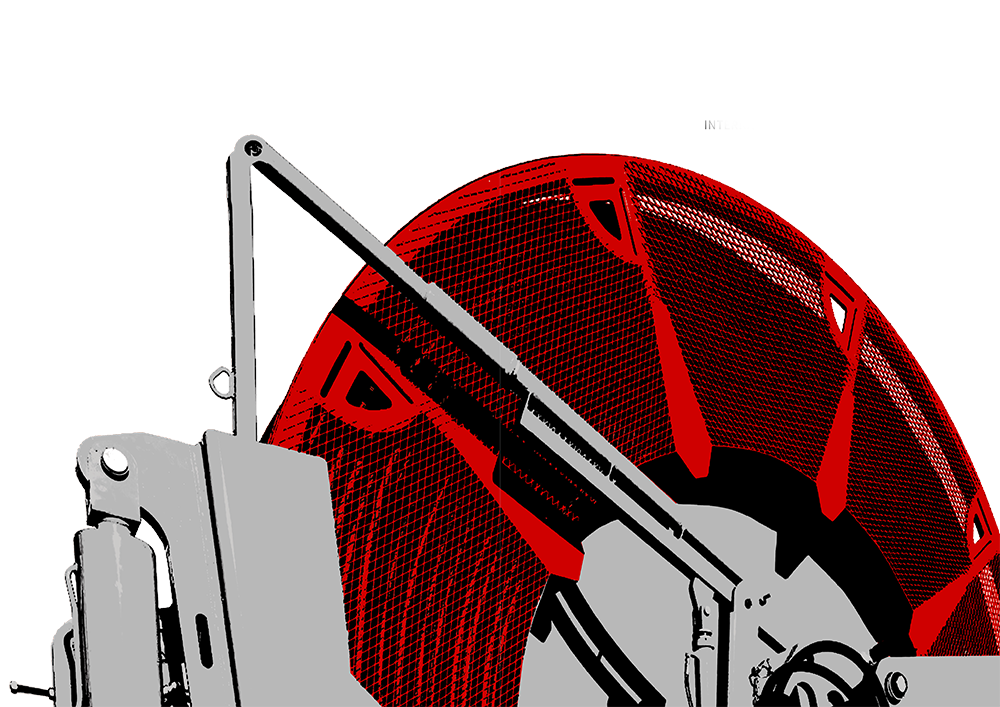

Coiled tubing is a continuous length of steel pipe spooled onto a large diameter reel. The pipe comes in a variety of sizes and can be run into any well.

Coiled tubing is commonly used to convey tools and circulate liquids and gases into and out of the wellbore without relieving the pressure.

Applications:

– Wellbore cleanout of fracturing or produced sand, scale, and wax

– Overbalanced/underbalanced milling and scraper treatments

– Placement and retrieval of production plugs, packers, and retainers

– Logging, perforating, and deployment of specialized completion tools

– Stimulation techniques including matrix acidizing and fracturing

– Provision of cement units with 15000 psi fluid end, high-tech mixing system, and automatic density

control.

– Supply of cementing additives from European sources

– Engineering Design is utilizing the most advanced cementing software

– Laboratory testing utilizing one fully equipped lab in the yard as well as one fully equipped portable lab

– Provision of a wide range of cementing accessories, including new technology cement heads, batch

mixers, fluid tanks, bulk handling silos, and equipment, Plus RTTS and packers.

– Lightweight cementing additives and monitoring technology with access to the solid fraction

monitoring equipment

– New technology solutions for acid-soluble cement, lost circulation, temporary plugs, brine flow

shut-off, gas migration

‘Stimulation’ is a generic term used to describe the process of increasing a well’s productivity through a specific type of operation. Hydraulic fracturing or acidizing are two commonly used stimulation techniques. Both processes are technically challenging, requiring extensive engineering and analysis beforehand to determine the appropriate type of stimulation treatment, the best chemical system, and the maximum pressure and fluid injection rates.

Matrix and fracture acidizing of sandstone and carbonate reservoirs are techniques for stimulating oil and gas reservoirs to produce at higher rates. Acids dissolve rock or permeability, damaging fines near the wellbore.

Successful acidizing requires a working knowledge of formation damage, acid chemicals, and the mechanics of acid stimulation techniques.

Our fully equipped equipment and experienced team with a variety of related accessories and engineering team, plus our lab with the capability of providing different brands and in-house chemicals are ready to serve the esteemed client.

Our pumping equipment fleet features a vast array of equipment, allowing us to select the right tool for the job. Pumping units are available in a broad range of configurations for both land and offshore applications, including basic pumping units, mixing/blending units, and multi-service units, which combine the capabilities of both sets of equipment for a more streamlined service offering and reduced footprint on location.

For energized flow or after stimulation lifting also Nitrogen Operation is applied for these operations: underbalanced drill (UBD), fluid Displacing, Gas lift, Flowing the well, etc. Thus Oil Exploration Operation Company is equipped with a high-pressure pump with a storage tank and mobile reservoir to have the best services to clients. Our 180K Nitrogen Units are designed to supply gaseous nitrogen at flow rates up to 180,000 SCFH (3000 SCFM) and pressures up to 10,000 PSIG.

IPON Thru Tubing intervention solution offers various types of downhole tools and equipment such as fishing & pulling activities, cutting, connecting & indexing activities, isolation activities, stimulation activities, etc. to perform thru tubing operations on a live well.

These tools enable us to perform tasks without the need for intervention, significantly increasing efficiency and lowering costs.

Through all drilling, testing, completion, and production stages, the wireline procedure will be extensively used for workover, data gathering, and operational requirements.

IPON Specialized Engineering’s Wireline & Completions Division provides the following services:

– DHSV service (install, function test, pull out, repair and maintenance)

– Running & Pulling Downhole Plugs & Safety Valves

– Shifting Sliding Sleeves

– Locating Tubing Ends, Bottom of Hole & Obstructions

– Downhole Sampling

– Tubing Caliper Surveys

– Paraffin and Scale Cutting

– Fishing Operations

– Tubular Perforations (Mechanical)

– Static Pressure / Temperature Survey (Using Electronic Quartz Memory Gauge, 15000 PSI)

– Flowing Pressure / Temperature Survey (Using Electronic Quartz Memory Gauge, 15000 PSI)

– Build-Up Pressure / Temperature Survey (Using Electronic Quartz Memory Gauge, 15000 PSI)

– Paraffin/Wax Removal

– Asphaltene Remedial Services

– Gas / Water Control in Oil Wells

– Supply / Replacement of Downhole Equipment Spare Parts

IPON provides cost-effective wellhead services.

Routine wellhead maintenance tasks we perform include:

– Lubricate/seal and function test gate valves

– Pressure test gate valves

– Function and pressure test valve actuators

– Pressure test casing/tubing hanger voids

– Record general wellhead condition (paint, corrosion, etc.)

– Wellhead Valves and Spare Parts Supply (Cameron, FMC, OCT, WKN, Orbit, Valve Italy)

– Wellhead Valves Maintenance (Cameron, FMC, OCT, WKN, Orbit, Valve Italy)

– Wellhead and Flowline Valves Inspection

– Hydrostatic Testing of Wellhead Valves

– Maintenance of Various Valves (gate, ball, plug, butterfly, and check valves)

– Installing / Repairing of Damaged Wellhead and Flowline Valves

– Greasing and Lubricating Wellhead Valves in Various Sizes

– Wellhead Patrolling (Pressure and Temperature Recording)

– Supply of Pressure and Temperature Gauges

– Fixing Leakage of Wellhead and Flowline Valves

– Repairing of Casing Side Valves

– Installation / Replacement of Wellhead Equipment Spool

– Supply / Replacement of Surface Chokes

OUR WELL SERVICES RESERVOIR TESTING

Well testing is the only method for fullscale reservoir evaluation under dynamic conditions. SWT

allows operators to evaluate characteristics of the producing reservoir, obtaining data such as

– Exploration and appraisal testing services

– Development well clean-up and well unloading services

– In-line production testing services

– Extended well tests

– High flow rate tests

– Limited flow tests

Other Services:

– Surface testing

– Multiphase flow meter

– Full bore Drill stem testing (DST)

– Mechanical DST

– Tubing conveyed perforation

– Surface and bottom hole PVT sampling

– PVT mobile laboratory

– Green burner system

The crude oil from the worked-over and/or newly drilled wells, which is sandy and acidic, was burned in burn pits for several days until the oil was available with a suitable and acceptable specification for transmission to production units. Burning dirty oil has been the main cause of serious environmental problems, such as environmental pollution. Besides, thousands of barrels of oil were getting burned and wasted.

– Saving 50,000 oil barrels per year

– Decrease Environmental pollution

– Corrosion damage reduction in production facilities

Our testing facilities are capable of being mount on a trailer for every treatment or testing reason. Also, our Smokeless (green) burner can complete the package.

Digital Oilfield (DOF) promises to achieve integrated operations to measure, model, and control the oil and gas field assets, where decisions can be made effectively and consistently by the right people at the right time. The Impact of technology can be huge across all stages of oil and gas exploration and production life cycle, such as reducing lifting costs, increasing or optimizing production and the economic potential of the reservoir(s), enhanced oil recovery, real-time interventions, and innovative solutions to optimize assets’ performance, and integrating the various functional silos within the organization and across its trading partners. A digitization initiative also helps address several challenges in a field that can limit innovation, optimization, cost savings, and access to information. IPON’s technical team and consultants have a decent background and knowledge of the Iranian field’s problems and difficulties. With the support of our reputable international consultants, we are ready to make available DOF solutions from A to Z. Our solutions cover all steps from Consultancy, Design, and Implementation and full support of DOF service.

GENERAL SERVICE

In Iran, we observe a structural shortening of chemical value chains. Petrochemicals, Fine chemicals, Intermediaries are increasingly imported from countries with feedstock, energy, or other advantages. This leads to higher supply risks, volatility, lead times, and new supplier structures. This trend is likely to continue in the next few years.

Based on this development, a solvent is needed for strong procurement within direct material sourcing such as concentrates. We have been able to set up the blending facilities in order to improve productivity, efficiency, safety, and supply chain transparency.

At the core of IPON Group, Our Logistics division is the heart for managerial and administrative tasks in the Group’s Logistics and Forwarding activities, mainly concentrating on freight forwarding. We have enjoyed a remarkable contribution to Iran’s transportation and logistics market by rendering comprehensive and standard services. We render comprehensive, flexible, time-defined, and standardized services for the import, export, and transit market.

We are proud to gather a certified and experienced team to perform the required tests in line with the local oil & gas industry needs. Therefore, by providing and using the most updated and latest technology and equipment in the industry, we have become committed to render the mentioned services in their best way. According to the previous and current projects, the following tests and services can now be provided in this company:

1- Cathodic protection

2- Coupon Corrosion

3- Corrosion probe

4- Trans Rectifier Reading And adjustment

5- Laser Alignment

6-Vibration Control

7- Thermography Via Camera

8- Thickness measurement (UT)

9- Insulation Test

We keep your camp in excellent shape and perform all activities from check-in to check-out in a quality manner. Our Camp Services which we are providing to our clients are including but not limited to catering, room services, housekeeping, laundry, telecom, landscaping, waste management, and garbage disposal. We aim to keep common areas up to the highest health and safety standards and perform regular cleaning of public spaces like offices and lobby areas, dining rooms, hallways, washrooms, recreation facilities, and fitness centers.

Having experience in establishing Computerized Maintenance Management Systems (CMMS) and performing the preventive maintenances, logistics, and engineering services in most parts of an oil treatment units, we have provided a monitoring and maintenance capacity for the company, which can undoubtedly provide useful support for its clients.

IPON Projects

PROJECTS WE DO

NISOC: National Iranian South Oil Co.

PEDEC: Petroleum Engineering & Development Co.

AOGC: Arvandan Oil & Gas Co.

IOOC: Iranian Offshore Oil Co.

ICOFC: Iranian Central Oilfields Co.

KOGPC: Karoon Oil & Gas Production Co.

POGC: Pars Oil and Gas Co.

NIDC: National Iranian Drilling Co.

KEPCO: Khazar Exploration & Production Co.

PETROPARS

SIPC: Sinopec International Petroleum Corporation

CNPC: China National Petroleum Company

ZNV: Zarubezh Neft Vostok Company

PROJECTS WE DID

Current Active Projects

– Stimulation and Well Test – located in South Azadegan Oilfield – Client: PEDEC

– Coiled Tubing Services – located in Khuzestan Province – Client: NISOC

– Well Test and Slickline – located in Khuzestan Province – Client: AOGC

– Coiled Tubing and Stimulation – located in Khuzestan Province – Client: AOGC

– DST Services – located in southern provinces – Client: Private Company/NISOC

– Slickline – located in Aban & West Paydar Oilfield – Client: Private Company/ICOFC

– Coiled Tubing – located in Bushehr Province – Client: Private Company

– N2 Generation and Pumping Services – located in Khuzestan Province – Client: NISOC

2014

3Projects

65Jobs

2015

2 Projects

65 Jobs

2016

1 Project

77 Jobs

2017

1Project

85 Jobs

2018

2 Projects

60 Jobs

2019

3 Projects

106 Jobs

2020

1 Projects

101 Jobs

2021

6Projects

130 Jobs

Contact With IPON

Tehran Office:

No. 68, Kajabadi St., Nelson Mandela Blvd. (Africa), Tehran

Ahwaz Operational Site:

Next to Sheyban Municipality Building, Sheyban District, Ahwaz

Ahwaz Office:

No. 45, West Torbat St., Golestan Blvd., Ahwaz

Abadan Office:

No. 3499, Parvizi St., Amiri St., Abadan

Khorramshahr Office:

No. 2004, Imam Reza Business Center, Khorramshahr

Kish Office:

No. 17, Hormoz Blvd., Amir Kabir Sq., Kish Island